Think wholesale awnings are easy? Pick a style, check the price, place the order—done? Not quite. Many buyers end up stuck with unclear specs, shifting lead times, impatient customers, and unresponsive suppliers. Worse, during peak sales, new product launches, or urgent project deadlines, a tiny mistake can turn into a costly disaster.

LIDA OUTDOOR has specialized in exporting awnings for over a decade, working with hundreds of distributors and engineering projects across Europe, the Middle East, and beyond. We know that needs vary widely depending on your role and where you are in the purchasing process. This guide is based on real projects and breaks down the six most critical steps in awning wholesale—so you can stay sharp, steady, and efficient at every stage.

Start with You: Who Are You and What Do You Need?

Most buyers begin by asking, “What awning styles do you offer?” or “What’s in stock?”

But that’s not the smartest first move. Instead, start by asking yourself: Who are you in this deal? A distributor, an online seller, or a project contractor? What matters more to you—price, design, structure, or delivery time?

1) Your Buying Role Shapes Your Thinking

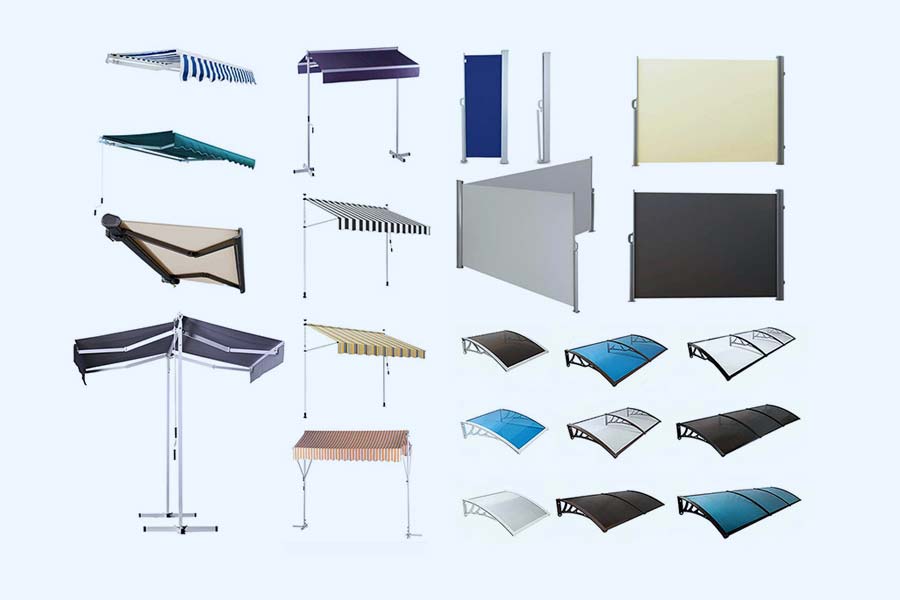

Are you a distributor? Then you’re probably focused on price and product flexibility—something easy to stock and quick to move. An e-commerce seller? You care more about trendy designs, eye-catching details, and maybe custom features that help you stand out. Running a construction project? You’ll need solid structure, easy installation, on-time delivery, and technical support like drawings.

Your role defines your needs. Figure that out first, and choosing the right awning product gets a lot easier.

Because every buyer has a different role, we offer different solutions to match. If your top concern is fast delivery, we’ll recommend standard models with in-stock options. And if you are looking to create a custom bestseller, we can share design sketches and popular color trends.

2) Lock in the Right Specs Early

A lot of buyers assume awnings are simple—just choose the style, color, and size. But when it comes to production, missing the fine details can turn into a rework nightmare. Here are the must-confirm specs you should align on from day one:

What specs should you confirm?

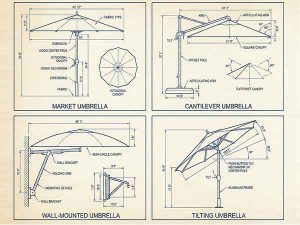

- Structure type: Free-standing, side arm, or retractable? Manual or motorized? These choices impact both how it’s used and how much it costs. Click to know 5 popular awning types >

- Fabric material: Are you focused on sun protection, waterproofing, or overall visual appeal? Common options include polyester, acrylic, and PVC-coated fabric—each with its own benefits.

- Colors and sizes: Are trending colors available? Can custom shades be ordered? Are standard sizes ready to ship? These all affect how fast you can launch or deliver.

- Customization: Do they support logo printing or branded packaging? Are templates available? E-commerce and brand buyers care about this a lot.

- Protection performance: Does it block UV? What’s the waterproof rating? Can the supplier provide certified test reports? For markets like the US and EU, this is often the key to clearing customs and passing customer checks.

We suggest confirming all these specs upfront during early communication. Don’t hesitate to ask detailed questions—the clearer things are now, the fewer issues you’ll face later. Whenever possible, request real samples or test reports. Seeing and feeling the materials will help you avoid back-and-forth revisions or costly shipping errors down the line.

Choosing the Right Supplier Is Step One

Great products alone aren’t enough. What really determines your project’s success is your awning supplier’s export experience and willingness to cooperate. Don’t be fooled by a flashy trade show booth or polished social media posts. A truly reliable factory should stand up to tough questions in these areas:

1) Export Experience, Sampling Skills, and Audit Readiness—All Matter

A large-looking factory doesn’t always mean it’s ready for export. Focus on these four checks:

- Do they have a stable export team? Can they communicate smoothly in English or other languages? Have they handled orders across multiple countries? If not, expect a lot of confusion.

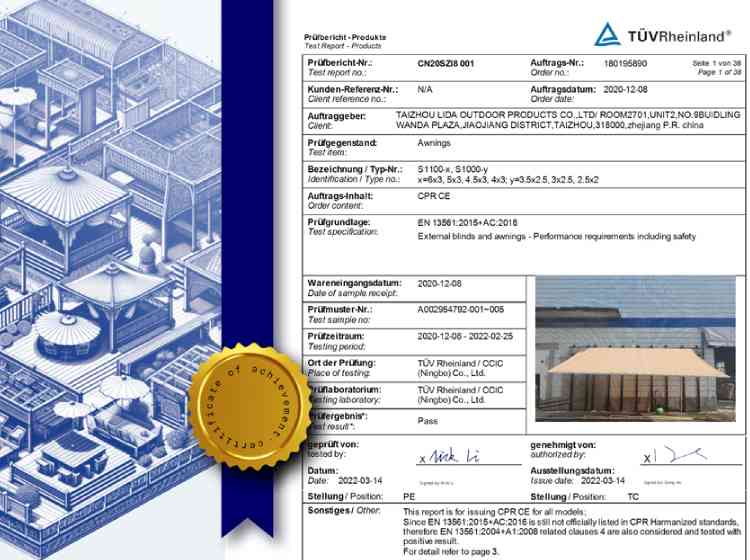

- Do they know your market’s standards? CE and REACH for Europe, fire resistance for the U.S.—a qualified awning manufacturer or supplier should proactively point out what matters for compliance.

- Is their sampling process professional? Can they offer standard sample forms, structural drawings, and size confirmations? A messy sampling process leads to mass production risks.

- Can they support audits or provide certifications? Suppliers who offer BSCI, ISO, or SEDEX documents—or welcome third-party audits—show they’re open, transparent, and worth long-term cooperation.

You can also look beyond words—check out factory videos, past export samples, or container loading photos. These real-world details often reveal more about a supplier’s hands-on experience than any catalog ever could.

2) Customization Response and Quality Control Define Long-Term Success

Awnings may look simple, but making them right—especially for projects or branded products—is often complex. Here’s how to tell if a supplier can truly handle it:

- Are they flexible with custom requests? Can they adjust size, structure, and color quickly? Do they offer technical drawings and practical suggestions, or just say “tell us what to do”?

- Is their sampling and confirmation process organized? Look for a clear process—like structural sketches, packing diagrams, and customer approval forms—to reduce back-and-forth.

- Is their quality control systemized? Do they manage quality from raw materials to final products, with proper inspections and standards—not just “the worker said it’s fine”?

- Do they have real after-sales support? If issues come up, can they reship? Can they trace the problem? Reliable factories usually keep full QA logs and reshipment records.

Manage Lead Times—Don’t Let Time Become Your Biggest Cost

Finding the right supplier is just the beginning. The real test? Whether they can deliver on time. Awnings may seem simple, but production involves fabric cutting, frame customization, packaging, and shipping. If any step gets delayed, the entire delivery timeline can fall apart.

1) Estimate Standard Lead Times—Don’t Let Time Become a Hidden Cost

Here’s a general lead time reference for awning products:

- Standard production usually takes 30–35 days.

- During peak season (September to June), it may stretch to 60–70 days.

- For custom samples, add another 5–10 days for confirmation.

When to place your order:

- For regular purchases, start production planning at least 45–60 days in advance.

- For e-commerce launches or seasonal campaigns, plan 70–90 days ahead, including time for sampling, production, and customs clearance—so you don’t miss your sales window.

2) Flexible Shipping Options—Handle Rush Orders, Split Shipments, and Stock Planning Together

What if you’re in a rush?

Check if the supplier has a “rush order” system. Some experienced factories offer fast-track lines that allow priority production—often with clear timelines and extra fees explained upfront. This kind of flexibility is a lifesaver if your project timeline changes midway.

Can you split shipments?

Absolutely. You don’t always have to wait for the full order to be ready. For large-volume orders, ask about partial shipments or rolling deliveries—they help reduce storage pressure and get products to market faster. Top-tier awning suppliers may also stock raw materials or pre-make inventory for returning customers, speeding up repeat orders and giving you more breathing room.

Don’t Overlook Logistics—Awnings Often Fail at the Final Mile

Getting your goods shipped on time is only half the battle. The real finish line is delivering them safely and intact to your customer. Awnings have long frames, lots of small parts, and multiple fragile areas—so if the loading or packaging goes wrong, you could open a container full of damage.

1) How to Prevent Damage When Shipping Long Items

Common shipping risks:

- Frame deformation: Aluminum beams or support poles over 3 meters long can easily bend or get dented if they aren’t packed securely.

- Fabric damage: Awning fabric may tear, mold, or wrinkle if it’s not rolled properly or lacks moisture and scratch protection.

What proper packaging should include (ask your supplier directly):

- Reinforced cartons with foam lining

- Edge protectors with shrink wrap

- Steel pallet frames for long parts to prevent bending

- Packing diagrams or photos from past shipments to build confidence

2) How to Choose the Right Shipping Method? It Depends on These 3 Scenarios

- Full Container Load (FCL): Best for medium to large orders. Lower cost per unit, better loading stability, and less risk of damage. If you can fill a container—do it

- Less than Container Load (LCL): Works for small orders, but there’s a risk when awnings are packed with unrelated items. Long parts can get crushed or bent.

- Express or Air Freight: Only for samples or urgent needs—fast but expensive.

A good supplier will suggest the most suitable method based on your order and budget—not just wait for you to decide.

3) Shipping Documents Matter—They Reflect How Professional the Supplier Is

A proper shipment isn’t just about loading products—it’s backed by complete paperwork. Ask your supplier if they can provide:

- Container Loading Plan: Shows how long parts are placed, which areas need reinforcement, and what to unload first.

- Packing List: Clear count, dimensions, gross/net weight of each item.

- Commercial Invoice + Certificate of Origin: Required for customs clearance and tariff benefits.

- Declaration and Bill of Lading: Can they send you digital copies before shipping? That’s a big plus.

Don’t Waste Money—Control Payment Terms and Manage Risks

Whether it’s your first time buying awning from another country, payment is always a critical issue. Pay too early, and you risk delays with no leverage. Pay too late, and the factory may refuse to start production. A well-structured payment schedule is key to balancing safety with efficiency.

1) Common Payment Methods That Work

A typical approach is 30% deposit + 70% before shipment. This lets the factory start production while giving you space for inspection before final payment. For large orders or long-term clients, options like Letter of Credit (L/C) or staggered payments are sometimes used. For first-time deals, avoid paying 100% upfront—especially if you haven’t yet verified the supplier’s capabilities.

2) Don’t Fear Contracts—Fear What’s Missing from Them

A strong purchase contract isn’t just about the price and quantity. It should clearly spell out these four key points:

- Product specs: Are dimensions, fabric types, structure, and color codes clearly listed? Don’t let vague terms like “red” turn into surprises like “wine red.”

- Delivery timeline: When does the lead time start—from sample approval or order date? Is there a penalty for late delivery?

- Payment terms: Are the payment method and schedule clearly stated? (e.g., TT, wire transfer, or L/C)

- After-sales policy: What happens if items arrive missing, broken, or short in quantity? Will there be a refund or reshipment? Who covers the shipping? Is minor damage acceptable?

Pro tip: Always attach signed drawings, approval sheets, and sample photos to the contract. What’s on paper is what protects you.

3) Should You Use a Third-Party Inspection? For High-Value Orders—Absolutely.

If it’s your first time working with a supplier, the order is large, or the product is highly customized, we strongly recommend a Pre-Shipment Inspection (PSI). Trusted agencies like SGS, TÜV, or BV can do the job. One inspection may cost a few hundred dollars—but it can save you thousands in mistakes, delays, or lost sales.

If you skip professional inspection, at least don’t rely on luck:

- Ask your supplier to send video walkthroughs of key components and packaging.

- Request real product photos and self-check reports before shipment.

- Experienced suppliers often do this without being asked—which shows they’re confident in their quality.

Compliance Is the Gatekeeper—Without It, Everything Falls Apart

Placing an order is just the beginning. The real test of a mature supply chain is whether your goods can clear customs and legally enter the market. Many buyers overlook compliance requirements upfront—only to face shipment holds, returns, or even destruction at the port. That’s not just costly—it delays timelines and damages trust with your end customers.

1) Always Confirm Compliance Standards for Your Target Market

Awnings are large outdoor structures, and different countries enforce different rules on materials, structural safety, UV resistance, and fire protection.

- Europe: Typically requires CE certification and, in some cases, REACH compliance for environmental safety.

- United States: Focuses on flame resistance and structural stability. UL or NFPA certifications may be needed.

- Australia & Middle East: Often require special labeling for UV protection, corrosion resistance, or temperature tolerance.

Don’t just take the supplier’s word for it. Ask for actual test reports or certificates. For first-time collaborations, request scans of sample certificates plus the testing agency’s name.

2. What Are the Must-Have Documents for Customs Clearance? These 4 Are Non-Negotiable

Even if your product meets technical standards, missing paperwork can still get your shipment stuck at the port. Make sure your supplier can consistently provide these four core documents:

- Commercial Invoice: Clearly lists product name, quantity, unit price, total value, and trade terms (e.g., FOB, CIF).

- Packing List: Shows packaging details, gross/net weights, and volume—essential for customs checks at destination.

- Certificate of Origin (CO): Used to claim tariff discounts (under EU-China agreements, RCEP, etc.) and confirm legal origin.

- Bill of Lading & Declaration Docs: Without these, your cargo can’t be released from port.

Pro tip: Ask your supplier for a “standard shipping document checklist” and request digital copies before shipment. This gives you time to verify everything and avoid last-minute delays.

Conclusion

Wholesale awnings aren’t just about price. It’s a full-scope operation. Every step carries hidden risks and costs. Get it wrong, and you may face delays or even lose the order altogether. Whether you’re an e-commerce seller just getting started, a distributor needing fast restocks, or a project manager with tight delivery requirements, choosing a supplier who truly understands your needs is far more valuable than chasing the lowest quote. Responsiveness, expertise, and proven delivery experience are what ensure long-term success.

If you’re planning to source awnings from China with consistency and confidence, we’re here to help. LIDA OUTDOOR brings over a decade of export experience, deep familiarity with EU, US, and Middle Eastern market standards, and full support for OEM/ODM, custom drawings, reliable lead times, and complete shipping documentation.