When you need more weather resistance than fabric gazebos can provide, but want easier maintenance and better light management than metal structures offer, polycarbonate gazebos present the ideal middle ground. With excellent UV protection, superior impact resistance to traditional roofing materials, and attractive light transmission, they deliver the perfect blend of durability, functionality, and visual appeal.

As a professional manufacturer with over two decades of experience in gazebo and awning production, LIDA OUTDOOR has deep insights into selecting the right gazebo materials. In this article, our R&D experts will provide you with a detailed analysis covering what a polycarbonate gazebo is, its advantages over a regular plastic gazebo, suitable application scenarios, and key procurement considerations.

What is a Polycarbonate Gazebo?

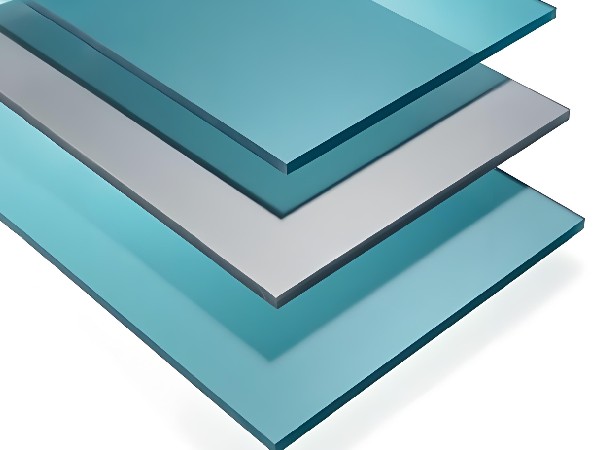

When people hear “plastic roof gazebo,” they often imagine cheap, flimsy covers that turn yellow and crack after just a few years. However, polycarbonate roofing operates at a completely different quality level than ordinary plastic roofing materials.

Polycarbonate is a high-performance engineering plastic widely used across multiple industries, including construction, aerospace, automotive, medical, and outdoor structures. It combines transparency, impact resistance, and weather durability, making it stronger than traditional plastics while being lighter and safer than glass. This is precisely why polycarbonate has quickly gained user recognition after being introduced to outdoor gazebo roofing.

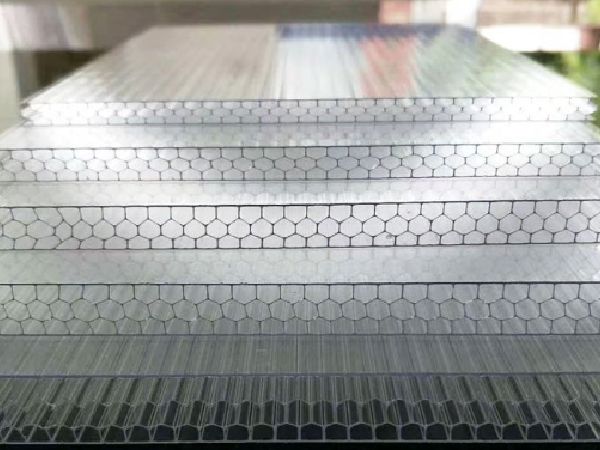

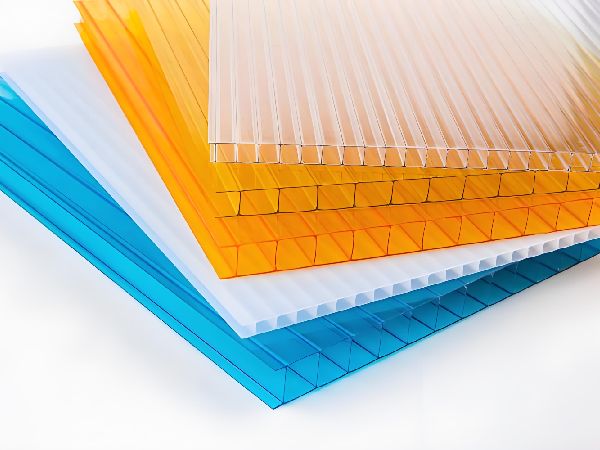

At LIDA OUTDOOR, we consistently use high-quality polycarbonate materials and can provide double-layer panels, honeycomb structure panels, or solid panels in any thickness according to customer requirements. Whether you prioritize strength, thermal insulation, or lightweight design with cost control, we can provide matching solutions. These structural designs not only offer excellent thermal insulation and UV protection but also effectively resist wind pressure and external impact forces, significantly extending service life. This is why our PC gazebo shipments continue to grow annually, earning trust from customers worldwide.

These types of gazebos have an extremely wide range of applications, extending far beyond residential backyards. For example, you can create a shaded area in your garden, build a semi-outdoor relaxation platform outside a café, or even use polycarbonate gazebos in landscape projects and commercial public spaces to enhance both functionality and overall sophistication.

Top 4 Core Advantages of Polycarbonate Roofing

Why are polycarbonate-roofed gazebos becoming increasingly popular, chosen not only by residential users but also appearing more frequently in various commercial projects? Whether you’re an end consumer or a B2B procurement professional, the characteristics of polycarbonate gazebos often precisely meet practical needs.

Of course, its advantages extend far beyond the four points we’re about to discuss. The following four aspects represent the key reasons why polycarbonate is widely used for gazebo roofing, and they constitute the core value proposition that enables it to quickly stand out in the market.

Four Core Advantages Overview:

| Advantage Dimension | Polycarbonate Performance | Technical Specifications/Parameters | Application Value |

| UV Protection/Anti-Aging | ⭐⭐⭐⭐⭐ | UV coating blocks >99% of UV rays; Tg ≈ 150°C | Extends service life, protects furniture and people, ideal for high-temperature climates |

| Impact Resistance | ⭐⭐⭐⭐ | Impact strength 10+ times greater than ordinary plastics | Withstands wind, rain, and hail; shatter-resistant with no sharp fragments, suitable for public or residential settings |

| Light Transmission & Comfort | ⭐⭐⭐⭐ | 89% light transmission with soft, non-glare illumination | Enhances spatial experience, perfect for outdoor tea areas, dining spaces, etc. |

| Weight & Installation Convenience | ⭐⭐⭐⭐⭐ | Density ~1.20 g/cm³, significantly lighter than glass/metal | Reduces structural load, supports DIY and rapid professional installation |

1. UV Protection and Aging Resistance

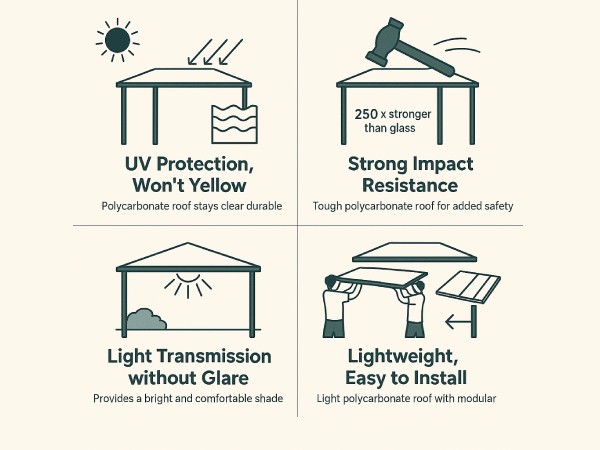

Polycarbonate panels typically feature UV-protective coatings that effectively block over 99% of ultraviolet rays, resisting yellowing and brittleness even under prolonged sun exposure, significantly extending service life. With a glass transition temperature (Tg) of approximately 150°C, it offers excellent heat resistance, making it ideal for high-temperature, intense sunlight outdoor environments. It not only protects the roof itself but also provides safer shade protection for furniture, flooring, and users.

2. Superior Impact Resistance for Enhanced Safety

Polycarbonate’s impact strength is over 10 times that of ordinary plastics, approximately 2 times that of ABS and 3 times that of PET, providing exceptional collision resistance. Even when subjected to strong winds, hail, or falling objects, it resists breakage, and if damage occurs, it won’t produce sharp fragments, ensuring safer use. This performance is particularly crucial for gazebos in areas with elderly or children’s activities, or those used in public spaces.

3. Light Transmission Without Glare for Enhanced Spatial Comfort

Polycarbonate achieves light transmission rates of over 89%, nearly comparable to glass. However, unlike glass, it doesn’t cause glare or become burning hot under intense sun exposure. It gently filters sunlight, providing brightness while reducing harsh heat. This “bright yet non-glaring” characteristic makes it particularly suitable for garden tea areas, outdoor dining spaces, poolside locations, and other scenarios requiring extended occupancy.

4. Lightweight, Flexible Installation, and Strong Structural Compatibility

With a density of approximately 1.20 g/cm³, polycarbonate weighs less than half that of traditional soda-lime glass. This makes it not only much lighter than glass but also easier to transport and install than metal roofing. The reduced weight means lower requirements for load-bearing foundation structures, significantly improving efficiency and reducing transportation costs for both residential DIY installations and large-scale commercial projects. Many manufacturers, including LIDA OUTDOOR, offer modular structures supporting flexible customization and rapid assembly, making them highly suitable for both retail and engineering project implementation.

These four advantages not only give residential users peace of mind but also make wholesalers and project contractors more willing to choose polycarbonate gazebos, because they truly achieve “lightweight structure, high performance, low maintenance.

How to Choose a Truly Reliable Polycarbonate Roof Gazebo

While polycarbonate roofing offers clear advantages, when making a purchase, “being PC material” is just the starting point, not the whole story. Factors such as panel thickness, structural design, and frame materials will directly impact the gazebo’s wind resistance, service life, and installation convenience.

Therefore, we’ll explain the key factors to focus on when selecting polycarbonate gazebos from both consumer (C-end) and business (B-end) perspectives. This way, whether you’re buying for personal use or bulk procurement, you can make your selection with confidence.

For residential users

We recommend focusing on these 4 key points when purchasing:

1. Adequate Roof Thickness

We recommend selecting PC panels with ≥6mm thickness, especially for year-round outdoor use or in regions with intense sunlight and strong winds. Greater thickness provides stronger compression and impact resistance, as well as better thermal insulation.

2. Double-Layer Structure Superior to Single-Layer Panels

Double-layer structures feature internal air insulation layers, providing not only better thermal insulation but also increased overall strength. This is more suitable for both high-temperature southern regions and cold northern winter areas.

3. UV Protection Coating and Shatter-Resistant Film Design

These features can further extend service life and reduce safety hazards. Particularly for balconies and children’s activity areas, we strongly recommend selecting panels with shatter-resistant safety coatings.

4. Frame Material Selection Cannot Be Overlooked

Aluminum alloy frames are lightweight, rust-resistant, and maintenance-free, making them the current mainstream choice; galvanized steel structures offer higher strength and are suitable for windy areas, but attention must be paid to whether anti-corrosion treatment is comprehensive.

For wholesalers and project contractors

You may want to focus on these 5 professional considerations:

1. Modular Design Compatible with Standard Packaging and Shipping?

Detachable, flat-pack designs are better suited for container shipping. Confirm whether product dimensions are compatible with 40HQ high cube containers, how many units fit per container, and whether they’re suitable for long-term standardized supply.

2. Does the Product Structure Support Customized Extensions?

Some projects require connected assemblies, corner treatments, or additions like rain gutters, lighting, and electrical pre-wiring. Choosing structurally flexible models can reduce on-site modification costs later.

3. Are Instructions and Educational Materials Comprehensive?

Whether multi-language installation manuals, pre-drilling diagrams, and structural numbering labels are provided, and if installation tutorial videos are available directly, impacts customer experience and installation efficiency.

4. Has It Passed European and American Standard Wind and Snow Load Testing?

If products are destined for markets like the US, Canada, or Northern Europe, recommend selecting products clearly marked with wind resistance ratings (such as 60-80 mph) and snow load parameters (such as 20-30 psf), ensuring relevant certifications or actual test data support.

5. After-Sales Parts Support and Warranty Policy

Can screws, brackets, and PC panels be supplied separately as replacements? Is a structural warranty provided (such as 3-5 years)? These factors determine whether channel partners are willing to establish long-term cooperation.

Conclusion

There are many gazebo products on the market, but few can truly balance “durability, aesthetics, structural stability, and installation convenience.” Polycarbonate gazebos are among the rare options that achieve comprehensive balance across all these aspects. They’re more wind and weather-resistant than fabric canopies, without fear of sun damage or brittleness; they’re also lighter and easier to install than metal roofs, with more controllable pricing.

Of course, a quality PC gazebo isn’t just about materials—it also depends on whether the structural design, installation hardware, and after-sales support are well-coordinated. And these are precisely the areas where LIDA OUTDOOR excels. If you have bulk gazebo procurement needs, please feel free to contact us anytime for relevant product information, and let’s work together to create more durable, worry-free outdoor spaces.